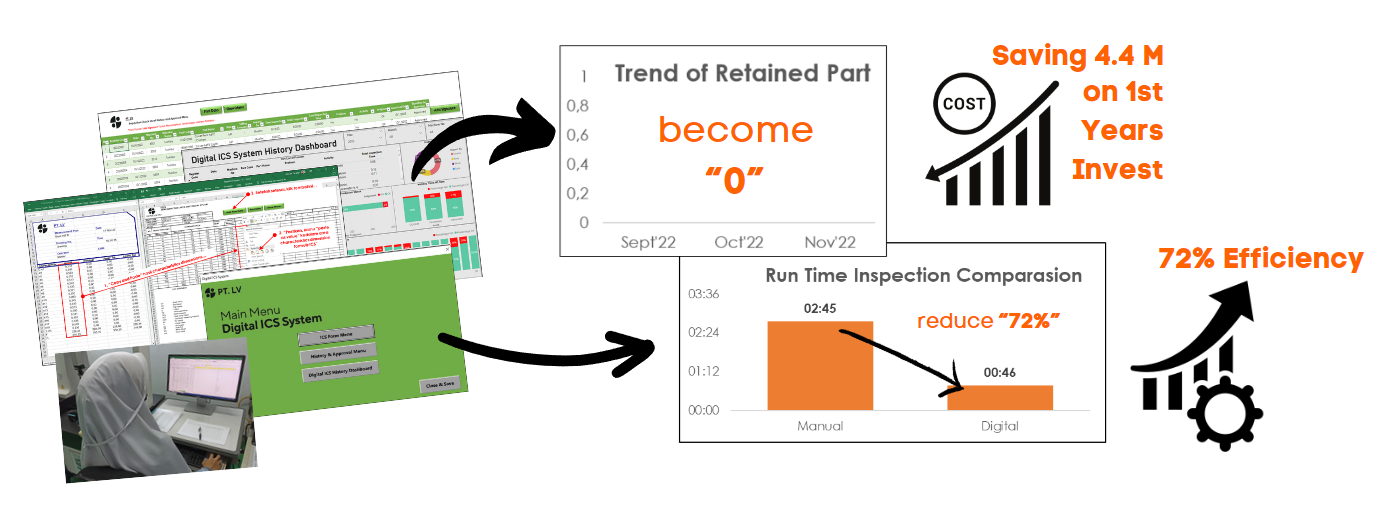

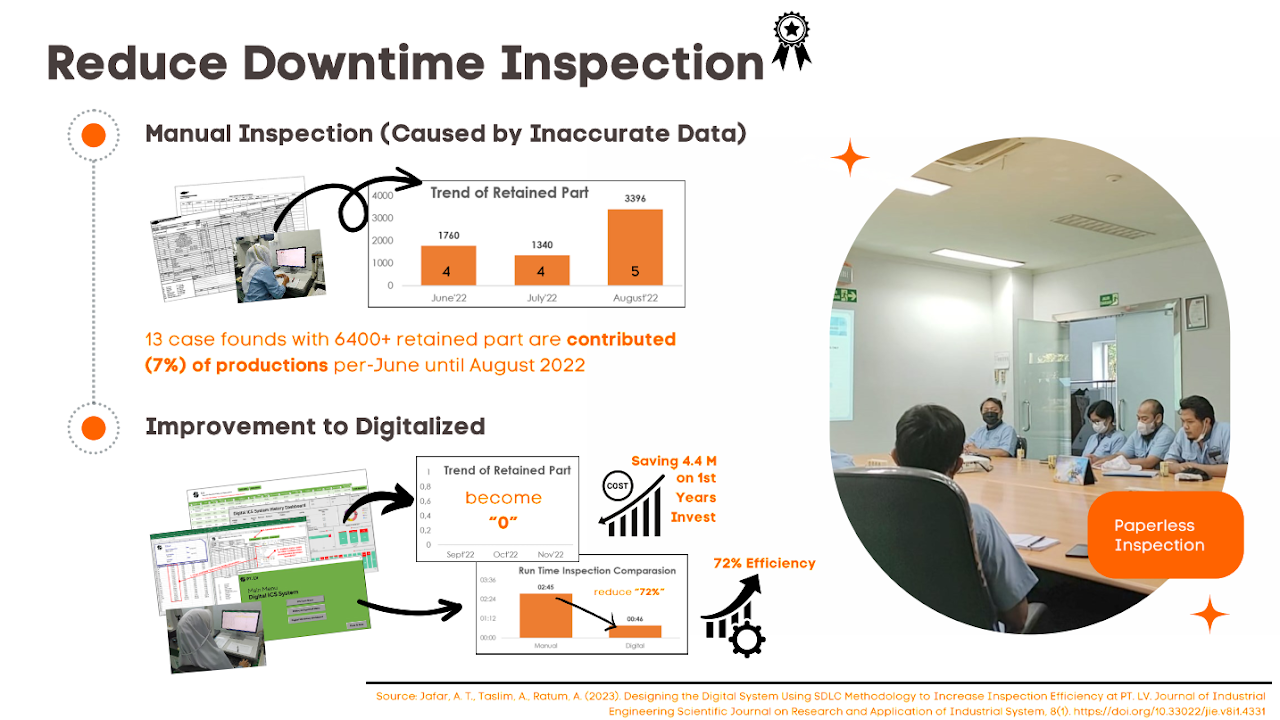

This project resulting automation measurement process and ICS (Inspection Check Sheet) digital system. So, downtime that caused by manual measurement and manual ICS (Inspection Check Sheet) document is resolving proof it increased the inspection efficiency by 72%.

Timeline

June - December 2022

— Project Details

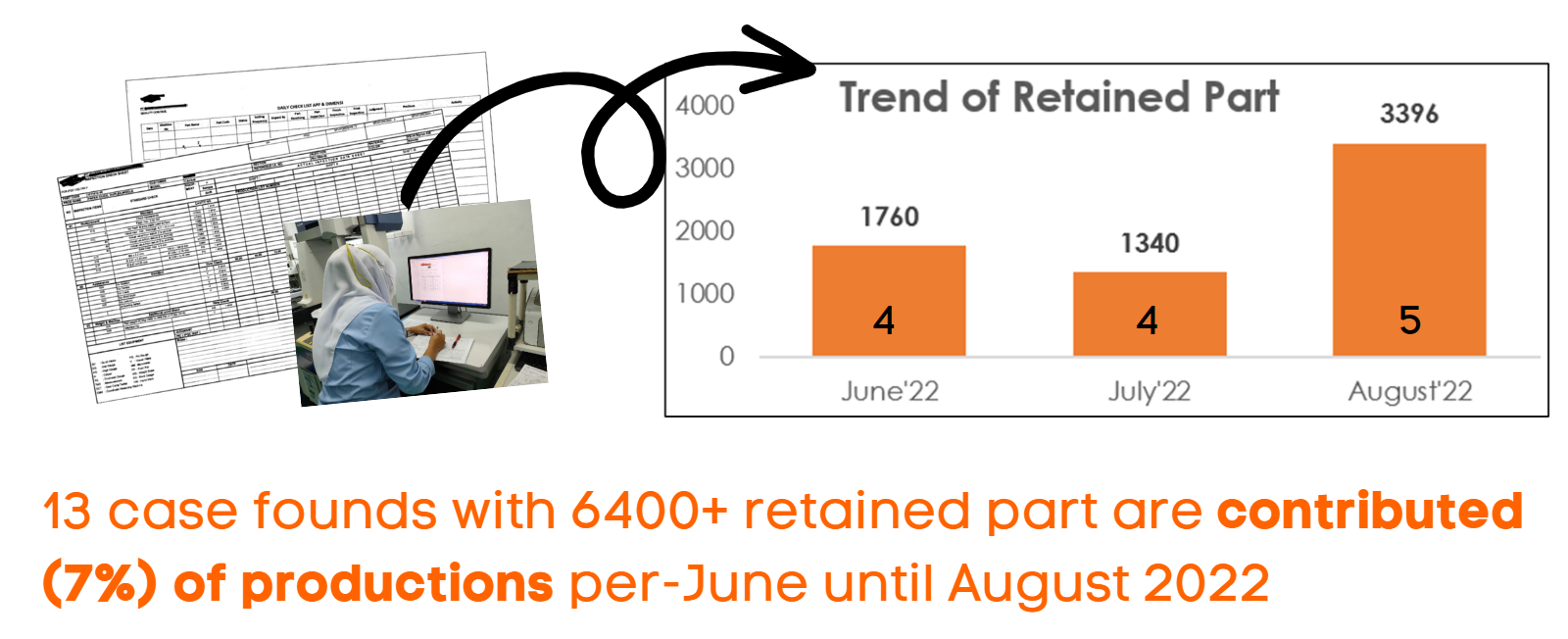

This project initiated by Jafar and collaborated with Senior Manager QA, PL Quality, & Factory Engineering. The purposes of project same like the title of project to Reduce Downtime Inspection. On June'22 until August'22 founded 13 Cases Innacurate Data that caused by manual measurement and manual data input after completed the measurement. There is 6400+ part retained where contributed 7% of a production.

With this situations the objective, and goals for this project are build. The target is to reach the Cases and Retained part become 0, and also Reduce Downtime Inspection of unecessary activity by Improving the measurement become automate using CMM and digitalize using Software that build by Excel worksheets.